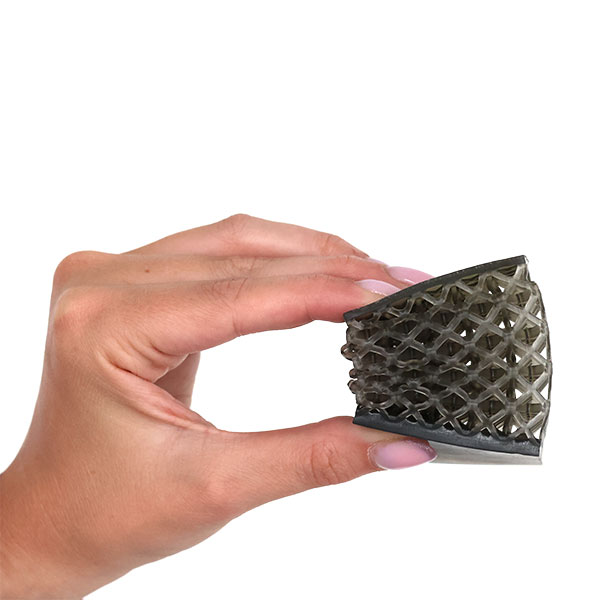

Flexible DL220 3D Resin

$405.00

Daylight Flexible Resin- ‘Flexible DL220B’ is an optimised solution for applications which require a combination of impact absorption, high elongation, efficient energy damping, good tear strength and exceptionally low water absorption.

5Kg

Best Used for:

• Sport protection, e.g., shin pads

• Shock and impact absorption, e.g., phone cases

• Cushioning

• Vibration damping, e.g., industrial machinery feet

USPs:

• Remarkable elongation at break >200%

• Slow rebound and efficient energy damping

• Exceptionally low water absorption (<1% after 7 days)

• High definition and resolution

• Easy to print due to its high green strength

Compatible Printers:

LC Magna (Not suitable for UV 3D printers)

Properties

Flexible DL220 Resin

Tensile Properties

Green

Post-cured*

Method

Tensile Modulus

Tensile Strength (Break)

Elongation at break

20 MPa

27 MPa

107%

66.4 MPa

14 MPa

211%

ASTM D412

ASTM D412

ASTM D412

Mechanical Properties

Tear Strength

Rebound Resilience

–

–

21 kN/m

19.6%

ASTM 624 Type C

ASTM D7121

General Properties

Shore Hardness

Water Absorption %* after 24 hrs

Water Absorption %* after 72 hrs

Water Absorption %* after 7 days

–

–

–

–

80 Shore A

0.32%

0.53%

1.09%

ASTM D2240

ASTM D570

ASTM D570

ASTM D570

Liquid Properties

Viscosity

Density

Storage

Color

–

–

–

1600 cPs

1.06 g/cm3

10<T>50°C

Black

At 25°C Brookfield spindle 3

* Post cured for 10 hours at 60°C with Photocentric Cure L2

Best Used for:

• Sport protection, e.g., shin pads

• Shock and impact absorption, e.g., phone cases

• Cushioning

• Vibration damping, e.g., industrial machinery feet

USPs:

• Remarkable elongation at break >200%

• Slow rebound and efficient energy damping

• Exceptionally low water absorption (<1% after 7 days)

• High definition and resolution

• Easy to print due to its high green strength

Compatible Printers:

LC Magna (Not suitable for UV 3D printers)

Properties

Flexible DL220B Resin

Tensile Properties

Tensile Modulus

20 MPa | 66.4 MPa*

ASTM D412

Tensile Strength (Break)

2.6 MPa | 14 MPa*

ASTM D412

Elongation at break

107% | 211%*

ASTM D412

Mechanical Properties

Tear Strength

21 kN/m

ASTM 624 Type C

Rebound Resilience

19.6%

ASTM D7121

General Properties

Shore Hardness

80 Shore A*

ASTM D2240

Water absorption (%)* after 24 hrs

0.32%

ASTM D570

Water absorption (%)* after 72 hrs

0.53%

ASTM D570

Water absorption (%)* after 7 days

1.09%

ASTM D570

Liquid Properties

Viscosity

1600 cPs

At 25°C Brookfield spindle 3

Density

1.06 g/cm3

Storage

10<T>50°C

Colour

Black

* Post cured for 10 hours at 60°C with Photocentric Cure L2

Reviews