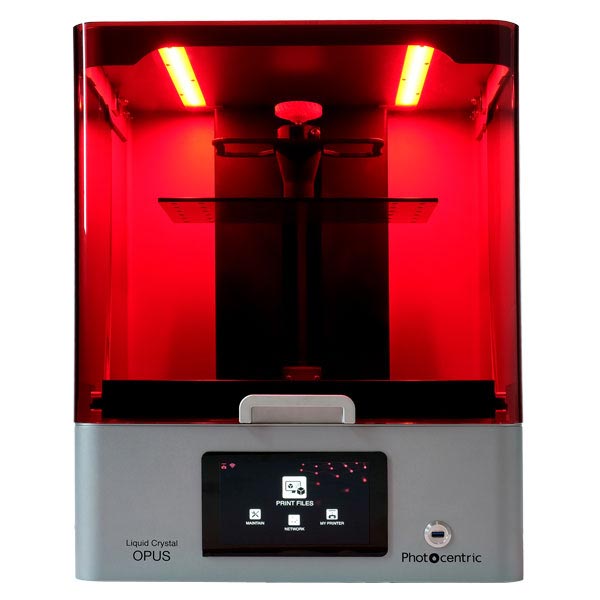

LC Opus

$8,815.00

From the inventors of LCD 3D Printing, the Photocentric LC Opus delivers fast, highly accurate prints suitable for a huge variety of industries and applications. With its rugged construction, the LC Opus has been designed to provide reliable and repeatable performance. Equally at home in a dental laboratory or engineering workshop, its intuitive and simple operation makes it perfect for beginners and experienced users alike.

Product Highlights

Impressive build volume of

12.2 x 6.9 x 7.9’’ (310 x 174 x 220mm)

XY resolution of 81μm provides scanned data accuracy of ≥95% at <100μm and ≥70% at <50 μm

Incredibly fast cure speed of 2 seconds per layer at 50μm layer thickness

A custom monochrome screen in a unique design supports consistent and reliable high performance

Photocentric’s patented peel release technology ‘Vat-Lift’ ensures reliability over large surface area printing

Robust double-sealed vat construction with practical carry handles and pouring spout

Full Technical Specifications

Performance

• Build volume: 12.2 x 6.9 x 7.9′′ (310 x 174 x 220mm).

• Print layer thickness: 25, 50 and 100μm. Layer thickness of >100μm is dependent upon resin properties.

• 14′′ monochrome 4k LCD screen.

• Print Speed: 18mm per hour.

• Cure Speed: 2 seconds per layer at 50μm.

• Light Output intensity – LCD screen: 5mW/cm²

• Resolution: XY resolution of 81μm provides scanned data accuracy of

≥95% at <100μm and ≥70% at <50 μm

• Photocentric’s patented peel release technology – ‘Vat-Lift’

• Light output wavelength: 405nm

User Interface and Operation

• Calibrated in the factory enabling quick set-up and installation on site.

• Large capacitive touch 7-inch screen.

• Integrated Photocentric control system

for optimum performance and in-field

updates.

• New vat with self-cleaning software option.

• Easy clean platform and chassis featuring robust double-sealed vat construction with practical carry handles.

• Screen cartridge with a tight tolerance facilitating easy replacement and easy servicing.

• Interchangeable platform options without recalibration – easier to handle, wash,

homing simplified.

Software

• Intuitive Photocentric STUDIO (software

licence)

Minimum System Requirements

• Operating System Windows 7, 8 or 10

• Minimum 2.0 GHz processor speed 2 cores – recommended 4 cores

• GPU capable of OpenGL version 3.0 or higher

• NET framework version 4.0

• 64bit system: recommended 4GB

• 32bit system: recommended 2GB

Connectivity

• Wi-Fi

• Ethernet

• USB 3.0 for fast file transfer

Construction

• Rugged aluminium construction with solvent resistant paint.

• 4k Monochrome 14′′ screen(3840 x 2160px with a pixel density of 314.7 PPI)

• Very flat, high tolerance glass.

• Platform print arm constructed from single billet of aerospace grade aluminium.

• Tough annealed red plastic hood is resistant to cracking from chemical exposure.

• Precision engineered components including THK linear rails from Japan.

• Trinamic motor drivers deliver extremely quiet and robust performance

• Ultra-quiet PWM fans provide efficient

cooling for high powered LEDs.

• Vibration damping rubber feet on base.

• Weight: 83.8 lbs (38kg)

You may also like…

-

UV LCD Dental Model Resin

$49.00 – $420.00 - 20% Off

UV High Tensile Resin

$61.60 -

LC Opus Vat Film x 5

$63.00 -

UV DLP Hard Resin

$77.00 -

Durable UV80 Resin

$105.00 -

Extended Warranty- Cure M+

$392.00 -

Extended Warranty- Photocentric Cure L2

$504.00 -

LC Opus Platform

$613.20 -

Extended Warranty- Photocentric AirWash L

$672.00 -

Photocentric Wash 15 + LC Opus Bracket & Lid

$835.00 -

LC Opus Vat

$950.60 -

Extended Warranty- LC Opus

$1,092.00 -

Photocentric Cure M+

$3,213.00 -

Photocentric Cure L2

$4,613.00 -

Photocentric Air Wash L + LC Opus Bracket

$5,978.00

Reviews